The global shift to smarter, electric cars is changing a key industry: automotive seat parts manufacturing. Components like slide rails and recliners are no longer just pieces of metal. They are becoming intelligent systems. This change demands more from automotive seat parts manufacturers. They must evolve from simple suppliers to essential engineering partners for car brands.

The New Goal for Seat Parts Suppliers: Creating Value, Not Just Parts

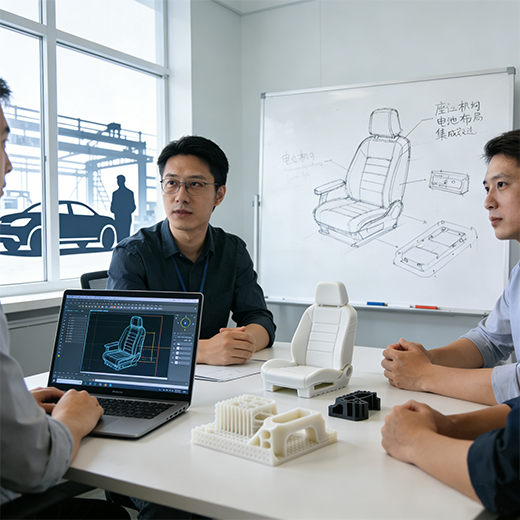

Historically, automotive seat parts suppliers were seen as cost centers. Today, this view is outdated. Car brands now compete on interior comfort and smart features. Consequently, they need partners who can co-create solutions. Leading manufacturers now engage early in the design process. They help solve complex challenges like weight reduction and space efficiency. This turns them from part makers into value enablers for the entire industry.

What Makes a Top-Tier Automotive Seat Parts Manufacturer?

To succeed today, a leading seat parts manufacturer must master four areas:

- Mastery of Precision Manufacturing: True expertise means controlling the entire production process. This includes precision stamping, machining, and automated assembly. Such control guarantees that every component, like a seat mechanism, meets the highest standards for smoothness and durability.

- Systems-Level Engineering Skill: The best manufacturers understand how their parts affect the whole vehicle. For example, designing a slide rail requires considering the car’s battery layout and safety structure, not just the seat itself.

- Uncompromising Quality Systems: Following international standards (like IATF 16949) is just the start. Top players set even stricter internal tests. They simulate years of use to ensure every part performs reliably over the vehicle’s entire life.

- An Agile and Reliable Supply Chain: The fast pace of the modern auto industry requires flexibility. Excellent suppliers build robust networks. This allows them to adapt quickly to design changes and urgent requests from their clients.

The Future of the Automotive Seat Parts Industry

Three key trends will shape the next decade for automotive seat parts makers:

- Smart and Interactive Components: Parts will integrate sensors and software. Imagine a recliner that automatically adjusts to your posture. This shift from manual parts to intelligent systems is a major opportunity for innovative manufacturers.

- The Green Materials Revolution: Sustainability is now a core requirement. The industry is rapidly adopting recycled metals and bio-based plastics. Future success depends on mastering these new materials and eco-friendly manufacturing processes.

- Collaboration Through Standardization: To manage complexity, car brands and their top suppliers will work together on standard designs. This allows manufacturers to produce efficient, platform-based kits that can still be customized.

Conclusion: Partners for a Human-Centric Future

The car of the future will be judged by its user experience. The seat is central to that experience. Therefore, the companies that design and build their core mechanisms are more important than ever. By mastering precision engineering, smart technology, and sustainable practices, forward-thinking automotive seat parts manufacturers are positioning themselves as indispensable partners. They are ready to co-create the next generation of exceptional vehicles.