In automotive engineering, safety and reliability are non-negotiable. Therefore, every component’s journey from design to installation requires rigorous proof. This proof is documented in a critical deliverable: the Component Testing and Validation Report. For systems like power seat adjusters, this report is not just paperwork. It is the definitive record that a product meets the highest standards before it reaches a vehicle. At Ningbo Chunji Technology, this validation philosophy is embedded in our core principle of “Professionalism, Quality, and Responsibility.”

Why Component Testing and Validation is Non-Negotiable

Every vehicle component must perform flawlessly for years. It must endure extreme heat, cold, humidity, and constant vibration. A comprehensive validation report provides the empirical evidence for this endurance. It transforms quality promises into verified, data-driven facts. Consequently, it ensures the seat lift mechanism remains reliable and safe for the vehicle’s entire lifespan. For Chunji, this rigorous process is the cornerstone of delivering “excellent quality, safe and comfortable products” to our clients.

The Chunji Framework for Component Testing and Validation

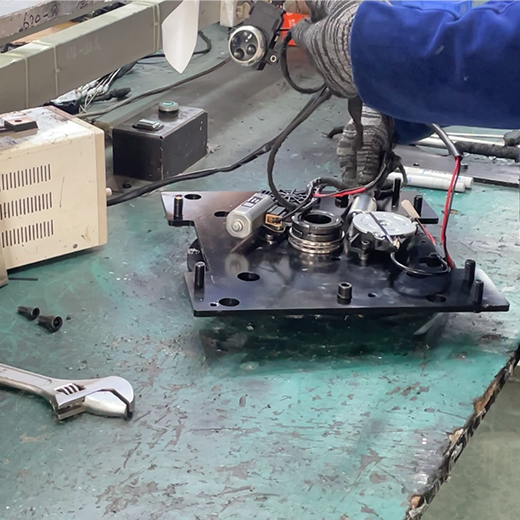

Our systemic commitment to quality is clear. It is reflected in our IATF 16949:2016 certification and 18 national patents. The validation process is not an afterthought. Instead, we integrate it into our complete manufacturing chain. This chain includes stamping, welding, riveting, coating, and precision assembly.

Our Component Testing and Validation Report covers several core verification areas. Each area simulates real-world stresses using our dedicated lab equipment.

1. Durability Testing: A Pillar of Product Validation

This is the cornerstone of validation. For example, we subject our dual-motor seat lift mechanisms and electric sliding rails to continuous, repetitive operation. This testing far exceeds normal use on dedicated endurance test benches. Each system must withstand tens of thousands of full cycles. Throughout this process, it must maintain smooth operation, consistent speed, and minimal noise. This proves the longevity of motors, gears, and structures, ensuring they won’t fail under daily use.

2. Structural Validation: Ensuring Integrity Under Load

Seat mechanisms must support significant dynamic loads safely. Our tests verify that components can handle maximum weight capacities with a substantial safety margin. We utilize microcomputer-controlled universal testing machines and pull gauges. These tools apply force not just statically, but also under simulated shock loads from sudden stops or impacts. This process validates the strength of our high-strength materials and ensures systems will not deform or compromise safety.

3. Environmental & Reliability Validation Protocols

A vehicle’s interior is a harsh environment. Therefore, our validation reports include data from exposing components to extreme conditions.

- Temperature Extremes: We verify functionality in high-temperature ovens and sub-zero chambers. This ensures motors and electronics operate reliably from extreme cold to desert heat.

- Humidity and Corrosion Resistance: Components undergo humidity cycles and salt spray testing. This prevents rust and keeps electrical connections secure over time, which is key for longevity.

- Vibration and Shock: Tests on shake tables simulate years of road vibrations. This ensures no fasteners loosen, no abnormal wear occurs, and no electrical connections fail.

4. Safety Validation: Verifying Critical Functions

This step confirms all designed safety features work as intended. For our mechanisms, this includes validating:

- Overload Protection: Systems must safely shut down or stall without damage if movement is obstructed.

- Secure Locking Positions: Mechanisms must firmly hold the seat at any point without slipping.

- Electrical Performance: Specialized equipment like slide rail current testers ensures electrical systems operate within strict safety parameters.

From Validation to Trust: Linking Reports to Standards

Our professional validation process aligns with global automotive standards. Furthermore, it supports overall vehicle compliance with stringent safety regulations. Our reference to organizations like the NHTSA underscores this commitment. Ultimately, this rigorous approach to creating a reliable Validation Report builds trust with our technical teams, procurement partners, and the renowned brands we serve.

Conclusion: The Foundational Role of Rigorous Component Testing

For engineers and specialists, a Component Testing and Validation Report is more than a document. It is the foundation of trust. It provides confidence that the chosen component is a dependable investment.

When you select a Chunji product, you choose more than a part. You choose verified safety, proven durability, and long-term reliability. Our dedicated Quality Control team and full technical support back every product. We are a partner committed to “keeping improving” and “perfect service.”

Interested in specifications or test summaries for our components?

Contact our technical team to discuss how our validated seat adjustment systems can meet your application’s precise requirements.